In today’s rapidly evolving technological landscape, one cutting-edge innovation that has gained significant attention is Liquid Silicone Rubber (LSR) injection molding. This groundbreaking manufacturing process offers numerous advantages and opens up new possibilities for industries across the globe.

The Advantages of LSR Injection Molding

lsr injection molding enables the production of complex and intricate designs with unmatched precision. Its ability to create parts with exceptional clarity, durability, and heat resistance makes it ideal for a wide range of applications in industries such as automotive, medical devices, electronics, and more.

Furthermore, LSR injection molding allows for efficient mass production due to its fast cycle times and minimal material waste. The process also ensures consistent quality control by eliminating variations commonly associated with manual labor or traditional manufacturing methods.

JVTECH: Pioneering LSR Injection Molding Solutions

When it comes to harnessing the full potential of LSR injection molding technology, JVTECH emerges as an industry leader. With their extensive expertise in this field combined with state-of-the-art facilities and equipment, they offer comprehensive solutions tailored to meet the unique needs of each client.

JVTECH’s team of highly skilled engineers work closely with clients from concept development through final production stages. Their commitment to delivering superior quality products on time has earned them a stellar reputation within the industry.

What is 2K Molding?

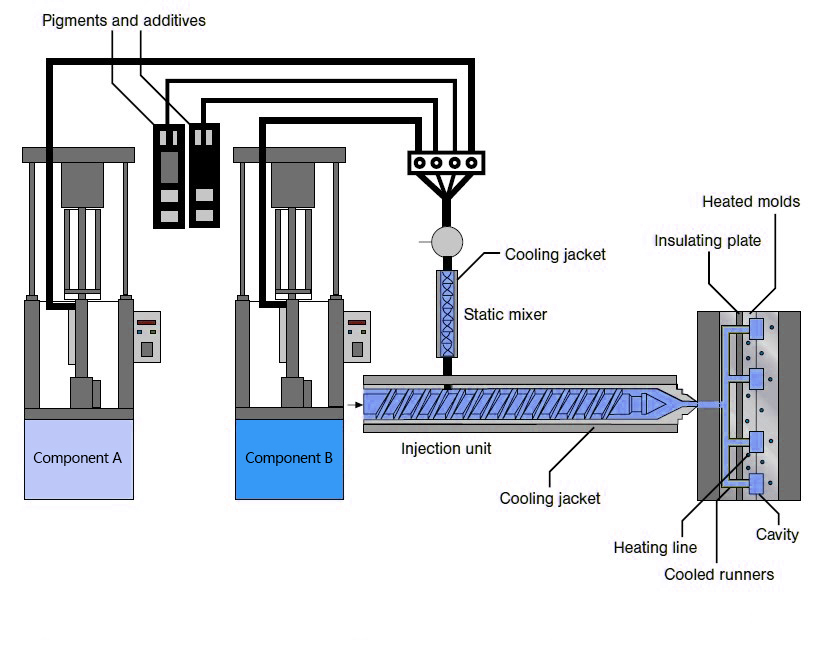

In addition to their proficiency in LSR injection molding, JVTECH specializes in another innovative technique known as 2K (two-shot) molding. This advanced method involves injecting two different materials into a single mold simultaneously or sequentially.

The benefits of 2K molding are manifold – it allows for the creation of complex parts with multiple colors, textures, or materials in a single manufacturing process. This not only saves time and costs but also enhances product functionality and aesthetics.

The Future of LSR Injection Molding

As technology continues to advance at an unprecedented pace, the future of LSR injection molding looks incredibly promising. With ongoing research and development efforts aimed at further enhancing its capabilities, this revolutionary manufacturing process is set to revolutionize industries across the globe.

From automotive components that require exceptional heat resistance to medical devices demanding biocompatibility and precision, LSR injection molding will continue to play a pivotal role in shaping our modern world.

Click what is 2k molding.